A Return Material Authorization (RMA) is a formal process between parties to initiate either a repair or replacement procedure. Keeping track of RMA’s is often a chore and documentation should be kept on the complete process. The manufacture will provide an RMA, or sometimes a case number to precede issuing an RMA if call-in support is initially required.

A field technician may not be able to initially call tech support but will want to start a process to get a problem corrected. Prior to contacting the manufacturer or supplier, collect specific information on the instrument or device.

Communication is always the key.

When a field technician calls in to discuss a problem instrument, my first question is, “Did you call tech support?”

Usually, tech support has not been contacted for reasons like the technician does not have the tech support number or was not able to get through to tech support. Sometimes the instrument is in a difficult place, like a submersible level probe. An error code could be displayed or a false reading to indicate a problem.

- Manufacturer

- Model

- Serial Number

- Issue

- Instrument or Device Tag

Initial information desired to begin equipment service

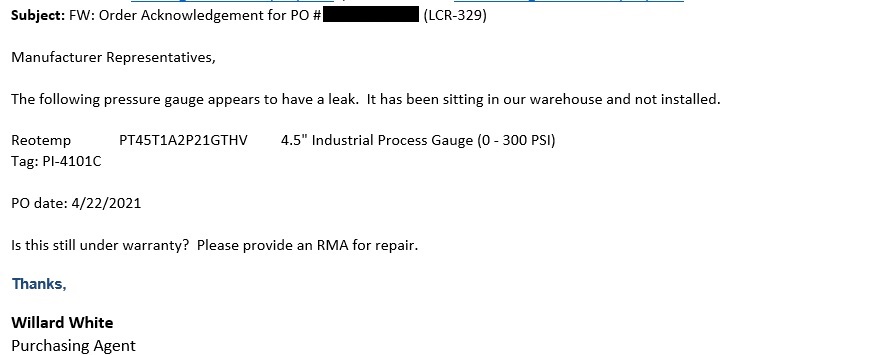

Once when I was rummaging through a box of field equipment which contained pressure transmitters and pressure gauges. One of the pressure gauge boxes was disfigured by fluid leakage. Since everything else in the box was dry, I opened the box and noticed the box interior had also absorbed fluid and the bubble in the pressure gauge was considerably larger than expected. To determine if the bubble was actually larger than expected, the gauge was compared with the other boxed gauges. Knowing the device would eventually be installed, I brought the possible fill fluid leakage to the project manager to be aware of the issue and get confirmation to begin repair before installation. The initial step selected for this issue was to contact the supplier. Since the supplier has a workbench set up to handle pressure gauges, it was most likely the supplier would request the gauge in their facility instead of returning to the manufacturer. The supplier, who is the manufacturer representative, is just as interested in what caused the leakage (bad plug? Incorrectly installed or a case manufacturing issue?) as they are in getting the device repaired.

Reotemp gauges are well made and of good design. This is the first from many years of using this manufacturer where a device was found faulty before installation. Usually lost fluid is caused from installation mishaps. Returning the gauge for repair was a simple process of contacting the supplier, providing the model number was all that was required because there was no serial number visible on the case. The attached stainless-steel tag indicates where the instrument goes in the facility infrastructure. The instrument has a nameplate also, but often the nameplate is not easily accessible or may be difficult to read depending on lighting conditions or installation location.

Since I am the purchasing agent for the company, I know where to find a considerable amount of missing information. If the Bill of Material (BOM) has the tag information, the information was also passed into the requisition software. The tag can be searched in the project data to pinpoint the device’s Manufacturer, Model, Description, and Supplier.

After I have received the most possible desired information from the field contact or have filled missing information from the project’s material data, I contact the supplier. The most efficient method I have found is to generate an email and include the collected information.

Most instruments come with a warranty. Sometimes instruments will be ordered and sit on the job site beyond their warranty period. Though the manufacturer understands project logistics where often installations get delayed, there is not much that can be done except to go through the repair process and pay.

A method to escape the warranty expiration problem is to order material in accordance with installation schedules. Unfortunately, as the COVID years of the 2020s and succeeding material shortage years led the world to exceptionally long delivery times, projected delivery schedules and Just-In-Time delivery was all but impossible.

This is a developing article. Please check back for updates.